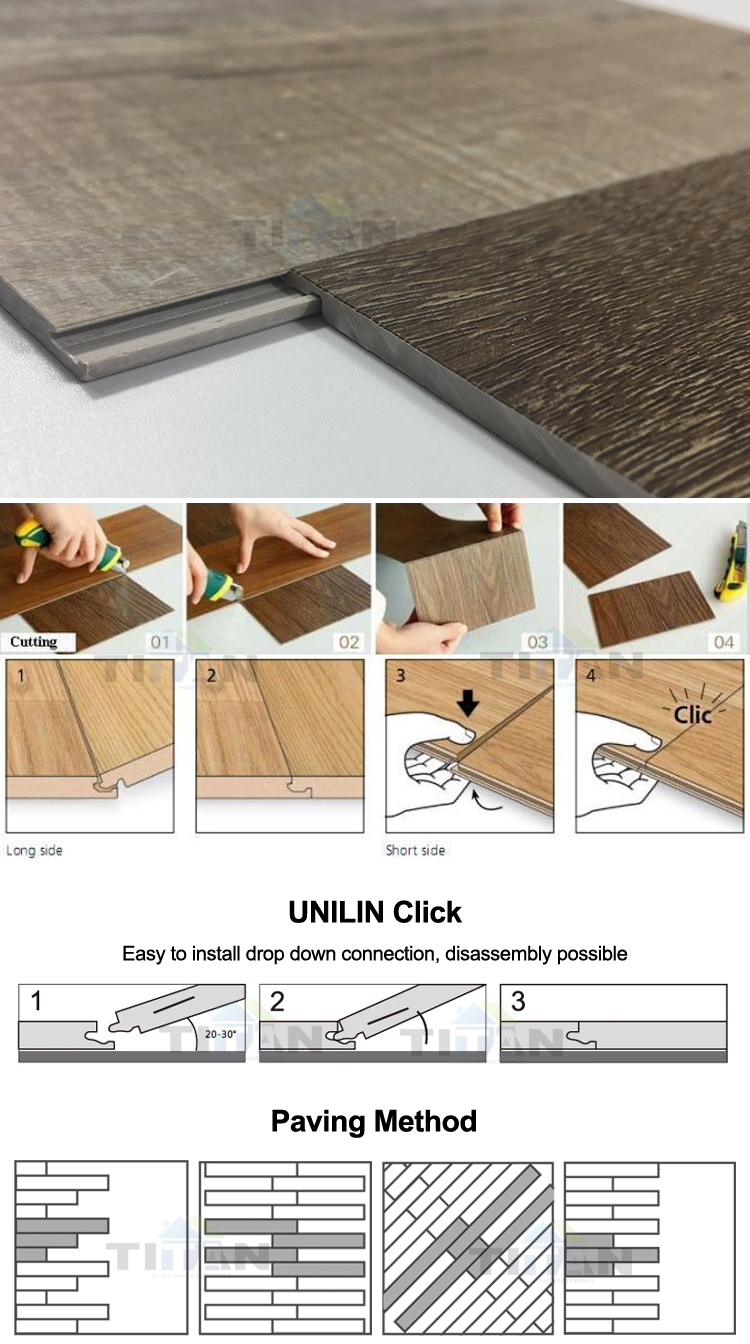

Installation should begin with a corner and proceed from the wall with the tongue facing away from the wall. Allow a minimum gap of 3/8” (10mm) for product expansion. Transition moldings or baseboards will cover the gap. When laying the first row in a straight line interlock the short ends by inserting the tongue into the grooves at an angle of about 15 to 20 degrees. Install sequential plank on the short end (5.75”) and be sure to line up evenly. Place this first row along the chosen wall respecting the minimum gap by using spacers. Keep the seams tight between planks. You will feel and hear the click when locking the planks together to create a tight seam. There should be no visible gap between planks. If seams do not appear tight, pull the planks apart immediately and try again. When installing our SPC, it is strongly suggested to stagger the rows so that the short edge seams are not in a straight uniform line. To start the second row, measure and mark the plank, then using a straight edge and utility knife, score the plank and snap it. Interlock the first plank of the second row again at a 15-20 degree angle. For the next planks, interlock the short side first, leaving it slightly away from the long side and then slide it into the long side in the same manner. Start the third row with the last plank remaining from the previous row. Fitting around irregular objects is very easy with our SPC. Simply make a pattern out of heavy paper to fit around pipes or irregular objects. Place the pattern on the plank and trace. Cut along trace lines using a utility knife or heavy-duty scissors, and lay plank. Allow for expansion gaps along each wall. The humidity of a room can vary due to differences between the seasons. Therefore your SPC floor must be able to expand and contract in all directions. This expansion can amount to 2mm per meter (1/12 in. per 3.28 ft.), so the greater the surface area, the greater the room for expansion required. To allow for this variation, an 8-12 mm (5/16 in. -3/8in.) expansion gap is provided at all walls. A gap must also be provided around pipes or at thresholds or obstacle

QQ

QQ ALIBABA

ALIBABA E-mail

E-mail 13724122257

13724122257